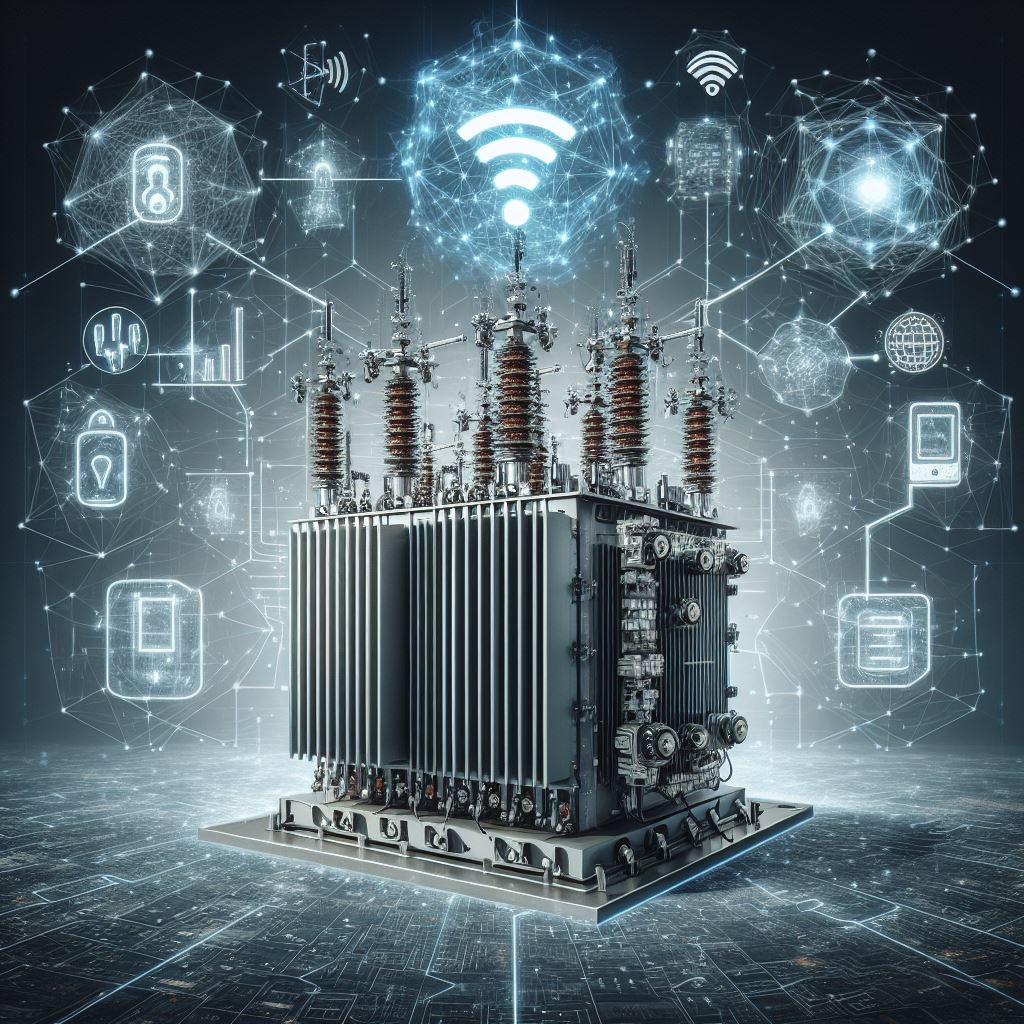

Power transformers are crucial components of the electrical grid, ensuring the effective transmission and distribution of power. However, these sophisticated systems are prone to malfunction, resulting in severe operational interruptions, financial losses, and possible safety issues. Fortunately, the incorporation of cutting-edge technology such as the Internet of Things (IoT) and Artificial Intelligence (AI) is changing the way utilities detect and control transformer failures.

IoT-Enabled Remote Monitoring: The Foundation for Proactive Maintenance

The traditional method to transformer maintenance has depended heavily on periodic inspections and manual data collecting. However, this reactive technique frequently fails to discover emerging difficulties before they develop into major failures. IoT-based remote monitoring devices provide a game-changing solution by collecting continuous, real-time data from transformers installed across the grid.

IoT sensors and devices are strategically positioned to monitor a variety of transformer characteristics such as voltage, current, temperature, and load capacity. This information is then wirelessly transferred to a central server for additional processing. By integrating IoT technology, utility operators have unparalleled access into their transformers’ health and performance, enabling for early detection of abnormalities and possible problems.

AI-Driven Predictive Analytics: Turning Data into Actionable Insights

While IoT allows for extensive data collection, the actual value resides in deriving useful insights from this plethora of information. This is where AI comes in, converting raw data into actionable insight using advanced analytics and machine learning techniques.

Artificial intelligence techniques used to analyse IoT data streams include neural networks, support vector machines, and decision trees. These models may learn from past data and recognise patterns that may warn prospective flaws or deterioration. AI algorithms can improve the accuracy of fault prediction models by using techniques such as feature selection and dimensionality reduction to identify the most important features and indications.

One significant technique is the combination of dissolved gas analysis (DGA) with AI-powered analytics. DGA includes analysing the gases dissolved in transformer oil, which can offer useful information on the existence and type of problems. When integrated with machine learning algorithms, DGA data improves problem detection accuracy and speed, allowing for faster reaction and service restoration.

Enhancing Reliability and Reducing Costs

The synergistic coupling of IoT and AI provides significant advantages for transformer failure prediction and management, eventually improving power system dependability and lowering operational costs.

1. Early Fault Detection and Prediction: By continually monitoring transformer characteristics and utilising AI-based analytics, prospective problems may be identified and anticipated well in advance. This preventive strategy reduces the chance of unplanned outages and significant breakdowns, resulting in a more dependable power supply.

2. Targeted Maintenance Strategies: The insights generated from IoT-AI integration allow utilities to optimise maintenance plans and allocate resources where they are most required. Rather of depending on predetermined maintenance intervals, predictive maintenance may be conducted based on the transformers’ current state, eliminating unwanted interventions and related costs.

3. Extended Asset Lifespan: Early identification and prompt repair may considerably increase the lifespan of power transformers, which are expensive assets. By rapidly resolving faults, utilities may extend the operating life of their transformers, avoiding costly replacements and lowering capital costs.

4. Improved operational efficiency: Real-time monitoring and AI-based analytics provide utility operators a complete picture of their systems, allowing for more informed decision-making. This increased operational transparency enables better resource allocation, optimised load management, and overall system efficiency.

5. Enhanced Safety: Transformer failures can offer serious safety issues, such as fires and explosions. By proactively recognising and addressing possible concerns, IoT and AI integration may help decrease these hazards, resulting in a safer working environment for utility professionals and the general public.

Overcoming Challenges and Embracing the Future

While the integration of IoT and AI in transformer failure prediction has significant benefits, it is not without hurdles. Data quality, security, and scalability are essential factors for effective adoption and long-term viability.

Ensuring the quality and dependability of data acquired by IoT devices is critical for successful analysis and decision-making. To deal with possible sensor faults, communication interruptions, and cyber threats, robust data validation and purification processes are required.

Furthermore, the massive volume of data created by IoT networks, along with the computing needs of AI algorithms, necessitates the use of strong data management and processing infrastructure. Cloud computing and edge computing technologies can assist utilities meet the scalability and performance demands of these sophisticated systems.

Despite these obstacles, IoT and AI have the potential to significantly improve transformer failure prediction and management. As the need for dependable and efficient power systems grows, utilities must embrace new technologies in order to remain competitive and fulfil their customers’ changing expectations.

Conclusion

The use of IoT and AI in transformer failure prediction and management offers a paradigm shift in utilities’ approach to asset management and power system dependability. By leveraging real-time data gathering and advanced analytics, utilities may shift from reactive to proactive, predictive maintenance practices.IoT-AI integration paves the way for higher dependability, lower costs, and longer asset lifespans through early defect identification, targeted maintenance, and more operational visibility. As these technologies expand and mature, utilities that embrace digital transformation will be better positioned to provide a more reliable and sustainable power supply, satisfying contemporary society’s ever-increasing energy demands.

Contact us at open-innovator@quotients.com to schedule a consultation and explore the transformative potential of this innovative technology