Video analytics, also referred to as video content analysis or intelligent video analytics, in recent times has been at the center of attention in both the industry and the academic world.

Advances in Deep Learning aiding Video Analytics

With advances in Deep Learning research and expanded availability of video data, video analytics now allows for the automation of tasks that were once possible by a human intervention only. This allows it to be used in a number of applications ranging from monitoring traffic jams and alerting in real-time, to analyzing customers’ flow in retail to maximize sales.

In Deep Learning, a subset of AI, a machine is exposed to volumes of tagged data allowing it to learn and recognize and identify the same information in new data sets imitating the way a human works. Deep Learning offers advantages like faster analytic output, improved processing performance, and increased object detection, accuracy, and classification.

Intelligent video analytics automatically recognizes temporal and spatial events in videos and performs real-time monitoring but it can also be used to analyze historical data to find insights. It can recognize objects, object attributes, movement patterns, or behavior related to the monitored environment are detected.

Some applications

Video analytics has the potential to be widely used in industries such as manufacturing, hospitality, education, retail, and others. We are discussing a few of them.

Healthcare

Integrating video analytics into legacy CCTV systems can transform cameras into much more proactive intelligence tools that can be used to ensure the safety of patients, staff, and visitors. Some of the most common problems like theft, infant abduction, and drug diversion can be detected and checked.

Mental healthcare is another area in which video analytics can be used to analyze facial expressions, and body posture to alert the hospital staff. It can also play a role in the at-home monitoring of older adults or people with health issues

Further, the data collected can be used to generate insights that can help to shorten wait times and achieve business goals by managing the staff according to patterns in the footfall of patients.

Transportation

Video analytics can be used in reducing accidents and traffic jams by dynamically adjusting traffic light control systems by monitoring traffic. By recognizing situations that may turn fatal in real-time, it can raise alerts, and even in the case of an accident, these systems can trigger an alarm to security and healthcare institutions to take action apart from that it can also serve as evidence in case of litigation.

Video analytics can also perform tasks like vehicle counting, speed cameras can detect traffic movements and license plate recognition can spots stolen vehicles or vehicles being used in a crime. It can also generate high-value statistics to assist in making infrastructure-related and other policy decisions.

Retail

The retail industry can use video analytics to generate insights and actionable information on customers’ behavior and buying patterns through their key characteristics like gender, age, duration and time of visit, walkways, etc. These algorithms can also be used to recognize previous customers and improve customer experience and provide personalized service. Video analytics can also play a role in developing anti-theft mechanisms by identifying shoplifters.

Manufacturing

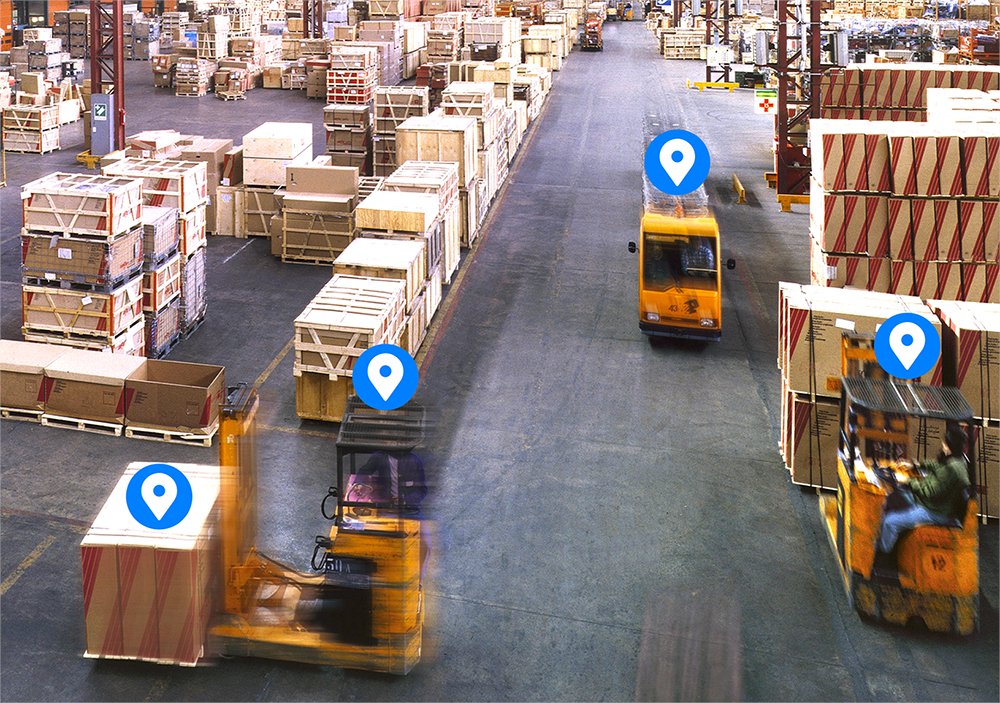

Video analytics can improve productivity, reduce downtime and ensure staff health at the manufacturing facility by enhancing operations and management efficiency.

Smart cameras can be used to predict potential interruptions, evaluate specific bottlenecks and reduce downtime by generating alerts to take proactive action immediately. It can also optimize the number of employees in the production facility and improve overall productivity. Inventory management can also be enhanced by analytics as the warehouses can be monitored for their capacity. The use of machine vision can help in inspection and improve quality control.

Video analytics can also warn of situations that may pose threats to people, products, or machines by detecting movements and identifying conditions. Video analytics can provide round-the-clock security and alert commercial as well as residential buildings and prevent potential break-ins.

Video Analytics Approach

Video content analysis can be done in real-time or post-processing. Also, it can be centrally on servers that are generally located in the monitoring station or can be embedded in the cameras themselves, some times a hybrid approach is adopted.

There are startups that are working on Video Analytics and have successfully deployed their solutions across various sectors such as hospitality, retail, manufacturing, pharma, and food. To more about evolving use-cases and startups in different domains please write to us at Open-innovator@Quotients.com