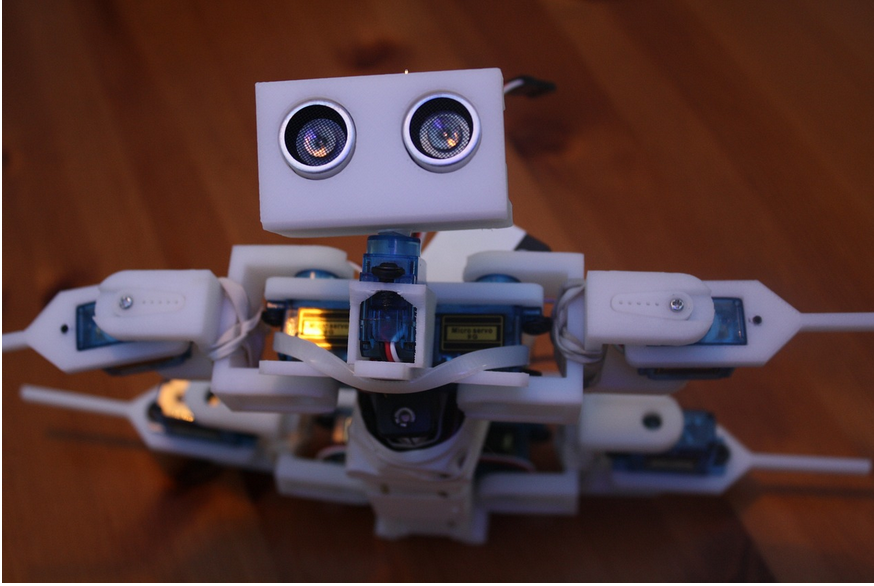

Introduction: The functionality of many gadgets and systems in today’s tech-driven society depends critically on one’s capacity to see and engage with the environment. One of the essential technologies for giving robots a precise sense of their surroundings is the development of ultrasonic sensors.

The way we see and interact with their environment has been completely transformed by ultrasonic sensors. They have become useful in a variety of sectors thanks to their capacity to deliver precise distance measurements and object recognition in different settings. As technology develops, we may anticipate that these sensors will become increasingly more crucial in determining the direction of automation, robotics, and other fields as well, ultimately making our planet smarter and safer.

Ultrasonic sensors measure distances using sound waves that are too high for us to hear. They use a transmitter to emit high-frequency sound waves, which are detected by a receiver after they reflect off of things. These sensors use the equation Distance = (Speed of Sound Time of Flight)/2, where the division by 2 accounts for the sound waves’ round-trip time, to compute distance by timing the time it takes for sound to reach an object and return.

Applications:

Ultrasonic sensors are widely used in a variety of sectors and are highly valued for their dependability and non-contact nature. They facilitate obstacle recognition and navigation in robotics, improving robot safety and maneuverability. These sensors are used in the automobile industry to ease operations like parallel parking and improve road safety by facilitating parking assistance and accident avoidance. Their accuracy in object recognition and distance measuring helps industrial automation by optimizing conveyor systems and manufacturing processes. Ultrasonic sensors are also used in the medical industry, smart home systems, agriculture, and the aerospace industry.

A groundbreaking development:

A revolutionary advancement has been made in the fields of temperature sensors and ultrasonic technology. The extraordinary ultrasonic temperature sensor is pushing the limits of temperature measurement in challenging situations, such as gas turbines and nuclear reactors, and it can monitor temperatures as high as 1000°C, where conventional sensors struggle to retain accuracy.

The sensor works in three steps as follows:

- An ultrasonic wave’s mechanical energy is first transformed into electrical signals using a piezoelectric transducer.

- Second, this transducer cleverly connects to a metallic waveguide that has a detecting tip to act as an ultrasonic wave conduit.

- Last but not least, the sensor monitors the waveguide’s resonant frequency shift, which fluctuates with temperature as a result of variations in the elastic elasticity of the metal, and provides accurate temperature measurements up to 1000°C in difficult settings.

Benefits, Obstacles, and Future Prospects

The ultrasonic temperature sensor has a variety of features, including:

- Robustness: The sensor is a sturdy option for demanding applications since it can endure harsh conditions in gas turbines and nuclear reactors.

- Simplicity: Despite utilizing cutting-edge technology, the sensor is still easy to use and understand.

- Precision and Stability: Even in the roughest settings, it excels in precision and retains stability.

- Reliability: The sensor regularly produces accurate readings, which is essential for industrial processes.

- Multiplexing Capabilities: Future research may investigate the use of many sensors concurrently, creating new avenues for data gathering and processing.

In summary, this unique advancement is a huge step in temperature measurement technology. For businesses that depend on accurate temperature monitoring, the ultrasonic temperature sensor’s ability to function in harsh environments while retaining high precision and dependability holds enormous potential. A new age of high-temperature measuring capabilities may begin as this technology develops and matures, potentially enhancing not just industrial processes but also the safety and effectiveness of crucial systems like gas turbines and nuclear reactors.

Are you intrigued by the limitless possibilities that modern technologies offer? Do you see the potential to revolutionize your business through innovative solutions? If so, we invite you to join us on a journey of exploration and transformation!

Let’s collaborate on transformation. Reach out to us at open-innovator@quotients.com now!