In today’s fast-paced business world, companies are continuously looking for methods to simplify processes, save costs, and increase competitiveness. Supply chain automation has emerged as a game changer, utilising cutting-edge technology to optimise operations and increase efficiency throughout the supply chain. Automation is transforming the way products and services are provided to customers, enabling unprecedented levels of productivity, visibility, and agility.

The Rise of Supply Chain Automation

Supply chain automation is the use of technology and software solutions to automate and optimise supply chain operations, therefore reducing the need for considerable human participation. This technique has gained popularity as firms seek to increase efficiency, minimise mistakes, and improve decision-making capabilities in their supply chain processes.

Key Benefits of Supply Chain Automation

1. Improved Efficiency and Productivity: By automating repetitive and time-consuming procedures, businesses may simplify processes, reduce redundancies, and free up valuable human resources for more strategic and value-added activities.

2. Cost Savings: Automated solutions eliminate the need for manual labour, decrease mistakes, and optimise resource utilisation, resulting in considerable cost savings over time.

3. Increased supply chain visibility: Real-time tracking and comprehensive analytics offered by automation provide unparalleled visibility into supply chain processes, allowing for proactive decision-making and quick response to interruptions or changes in demand.

4. Improved Predictive Analytics and Demand Forecasting: Using machine learning and artificial intelligence, automated systems can analyse historical data and market patterns to provide precise demand estimates, allowing for improved inventory management and resource allocation.

5. Regulatory Compliance: Automated procedures assure constant adherence to regulatory regulations, lowering the risk of noncompliance and the resulting fines.

Automation in Action: Key Applications

Supply chain automation comprises a diverse set of procedures and technology that allow organisations to simplify operations at various levels of the supply chain.

1. Back-Office Automation: Tasks like as invoicing, bookkeeping, and data entry may be automated with robotic process automation (RPA) and intelligent automation solutions, lowering the risk of mistakes and increasing productivity.

2. Transportation Planning and Route Optimisation: Advanced algorithms and machine learning approaches can optimise transportation routes by considering traffic patterns, weather conditions, and fuel prices, resulting in lower transportation costs and faster delivery times.

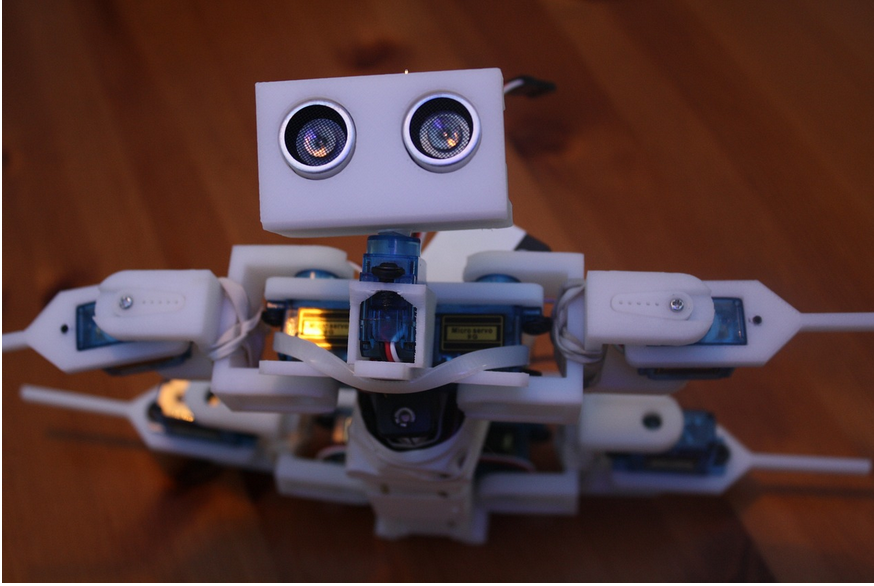

3. Warehouse Operations: Robotics, automated guided vehicles (AGVs), and intelligent warehouse management systems may automate tasks like as picking, packaging, and inventory management, increasing accuracy and efficiency while reducing human error.

4. Demand Forecasting and Procurement: Predictive analytics and machine learning models may use historical data, market trends, and real-time consumer demand to create accurate demand projections, allowing for proactive procurement and inventory management techniques.

5. Last-Mile Delivery: The combination of drones, autonomous vehicles, and powerful routing algorithms has the potential to transform last-mile delivery, lowering costs and improving delivery times for clients.

The Role of Emerging Technologies

Several cutting-edge technologies are propelling supply chain automation forward, allowing organisations to achieve previously unattainable levels of efficiency and flexibility.

1. Artificial intelligence (AI): AI is critical in supply chain automation because it enables technologies such as digital workforce, warehouse robots, autonomous vehicles, and robotic process automation (RPA) to automate repetitive and error-prone operations. AI enables back-office automation, logistics automation, warehouse automation, automated quality checks, inventory management, and supply chain predictive analytics/forecasting.

2. Internet of Things (IoT): IoT devices help provide real-time data and connection across the supply chain, allowing for better tracking, monitoring, and decision-making. IoT sensors in warehouses, cars, and goods collect data on location, temperature, humidity, and other factors to improve operations and visibility.

3. Generative AI (GenAI): Generative AI is a subclass of AI that focuses on developing new content, designs, or solutions from current data. GenAI may be used in supply chain automation to improve decision-making and efficiency through tasks such as demand forecasting, product design optimisation, and scenario planning.

Organisations may achieve better levels of automation, efficiency, and agility in their supply chain operations by utilising AI, IoT, and GenAI capabilities, resulting in increased productivity, cost savings, and improved decision-making skills.

Limitations and Considerations

While supply chain automation has many advantages, it is critical to understand its limitations and carefully consider its adoption. Currently, automation is confined to certain activities like order processing, inventory management, and transportation planning, while many procedures still require human intervention and supervision. Furthermore, the financial investment necessary for advanced automation technology may be prohibitive for smaller enterprises with limited resources.

Furthermore, the possibility of job displacement owing to the automation of manual work is a worry that must be addressed through retraining and upskilling programmes. Organisations must find a balance between automating processes and relying on human skills to make crucial decisions and handle exceptions.

The Future of Supply Chain Automation.

As technology advances, the opportunities for supply chain automation will grow even more. Organisations that embrace automation and strategically use the appropriate technology will be well-positioned to outperform the competition.

However, a balance must be struck between automation and human skill. While automation can help with many operations, human decision-making and monitoring are still required for handling outliers, unanticipated interruptions, and strategic planning within the supply chain.By combining the power of automation with human innovation, organisations may achieve new levels of efficiency, agility, and customer happiness, guaranteeing a sustainable and competitive supply chain in the future.

Contact us at open-innovator@quotients.com to schedule a consultation and explore the transformative potential of this innovative technology