The Fourth Industrial Revolution, or Industry 4.0, denotes a significant change in production and manufacturing methods. Automation, cutting-edge technology, and data are being combined to build “smart factories” that are extremely effective, adaptable, and networked. Artificial intelligence (AI), a game-changing technology that facilitates real-time data processing and decision-making, is at the core of Industry 4.0.

The Role of Automation and AI in Industry 4.0

In Industry 4.0, automation refers to the employment of computer-controlled systems to carry out jobs that were previously completed by people. This change improves product quality, lowers mistakes, and increases manufacturing efficiency. Higher output rates and constant quality are the results of automated systems’ ability to run continuously without becoming tired.

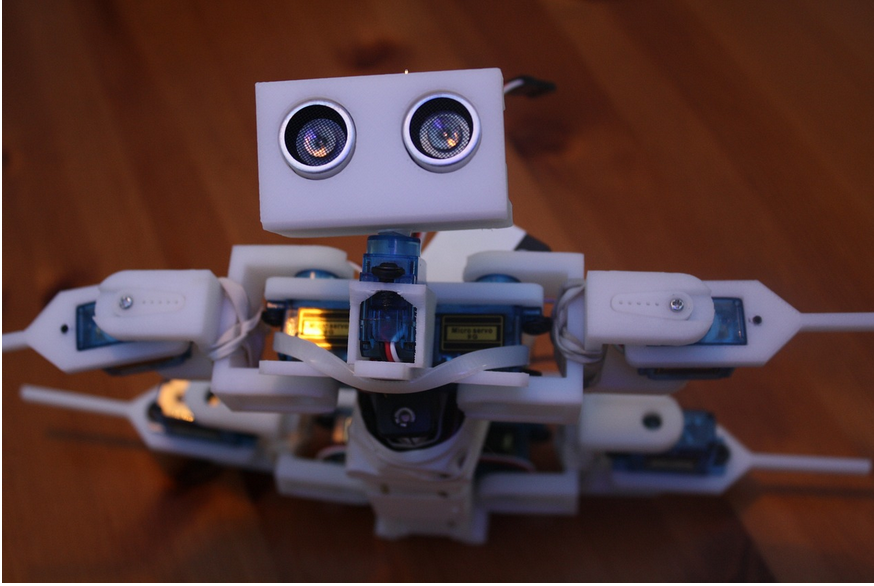

AI makes it possible for computers to learn from their experiences, adjust to new information, and carry out activities that previously needed human intellect, especially through machine learning. By giving software human-like comprehension, artificial intelligence (AI) improves automation and lessens the need for human interaction in production. AI-powered robots, for instance, are capable of product assembly, quality control, and real-time process adjustments based on data analysis.

How AI Benefits Industry 4.0

The Internet of Things (IoT) and artificial intelligence (AI) enable ongoing manufacturing process monitoring and optimization. Machine sensors gather data, which artificial intelligence systems then examine to find inefficiencies and recommend fixes. Waste reduction, better product quality, and enhanced overall efficiency are the results of this ongoing feedback loop.

Predictive maintenance is one of the biggest advantages of AI in Industry 4.0. AI can evaluate machine data to forecast when a part is likely to break, enabling prompt maintenance and avoiding expensive downtime. This proactive strategy guarantees smooth operations and increases the equipment’s lifespan.

AI may identify tiny irregularities and underlying causes of production issues that may go unnoticed by humans through machine learning and ongoing analysis. AI makes it possible to intervene quickly by spotting these problems early, guaranteeing that only superior items make it to market.

AI is essential for improving worker safety. AI-powered solutions are able to keep an eye on workplaces, identify any risks, and notify employees to take precautions. AI, for example, may examine video footage from manufacturing floors to spot dangerous practices or broken machinery, lowering the possibility of mishaps.

AI is quite good at finding patterns and trends in big datasets. AI may be used in Industry 4.0 to forecast market demand based on consumer behavior and consumption trends. This feature lowers overproduction and stockouts by enabling manufacturers to match their production schedules with market demands.

One cutting-edge use of AI that supports the design stage of product development is generative design. Based on predetermined characteristics, such material attributes and production restrictions, AI algorithms may produce a variety of design possibilities. This method speeds up the design process and makes it possible to use 3D printing to create efficient, reasonably priced prototypes.

AI analyzes data and locates bottlenecks to optimize a variety of production processes. AI increases production, lowers downtime, and raises the caliber of the finished product by making modifications in real time. AI may, for instance, modify resource allocation and manufacturing line speeds to guarantee optimal efficiency.

AI makes it easier to use less energy and materials, which lowers production costs. Production planning may be optimized by AI algorithms, guaranteeing waste reduction and effective resource usage. This feature is especially useful in sectors like manufacturing and logistics that use a lot of energy.

Challenges of Automation in Industry 4.0

Large investments in new technologies are necessary to make the shift to Industry 4.0. Significant financial resources are needed for staff training, infrastructure upgrades, and the deployment of AI-driven automation solutions. To make wise judgments, businesses must balance the upfront expenses with the long-term advantages.

The workforce must adjust when routine and repetitive duties are replaced by automation and artificial intelligence. It is crucial to retrain staff members to operate efficiently with cutting-edge technology. Employees must reskill and upskill in order to meet the evolving needs of the digital era. To guarantee a seamless transition, businesses must fund education and training initiatives.

Large volumes of data are produced by Industry 4.0’s combination of AI and IoT. A major difficulty is ensuring data security and privacy. Strong cybersecurity measures must be put in place by businesses to shield private data from breaches and assaults. Furthermore, adherence to data privacy laws is necessary to preserve client confidence and stay out of trouble with the law.

Key Takeaways

Automation and artificial intelligence are driving a revolutionary age in manufacturing and production known as Industry 4.0. Demand prediction, generative design, process optimization, quality control, increased safety, increased efficiency, and improved resource management are just a few advantages that these technologies provide. But there are drawbacks to the shift to Industry 4.0 as well, such high costs, shifting labor, and data security issues.

AI is a key component of Industry 4.0, offering the adaptability and agility required to address logistical, production, and supply chain issues. Manufacturing is expected to become more inventive, sustainable, and efficient in the future as businesses continue to use AI and automation. Businesses can fully realize the promise of Industry 4.0 and prosper in the digital era by investing in cutting-edge technology and upskilling their employees.

Reach out to us at open-innovator@quotients.com or drop us a line to delve into the transformative potential of this groundbreaking technology. We’d love to explore the possibilities with you.